Appareils de manutention

Showing 21–40 of 44 results

Qu'est-ce qu'un appareil de manutention ?

Les appareils de manutention sont des machines spéciales. Elles sont conçues dans le but d’accompagner les entreprises dans l’adaptation des postes de travail présentant des tâches répétitives et pénibles.

En effet les différentes gammes d’appareils de manutention lutte contre les troubles musculo squelettiques. Ils sont pensés et fabriqués de manière à faciliter les opérations mais aussi à limiter les efforts fournis par les opérateurs (trice)

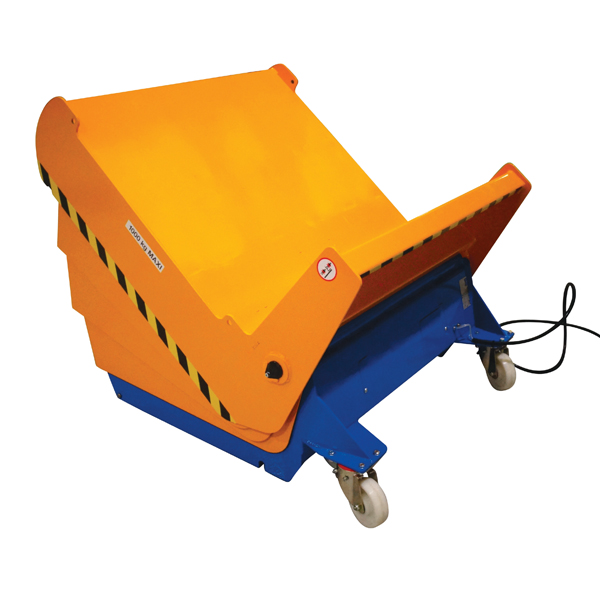

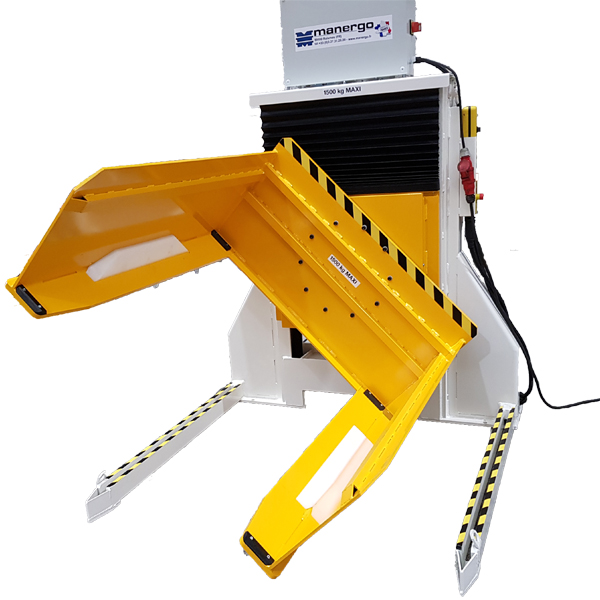

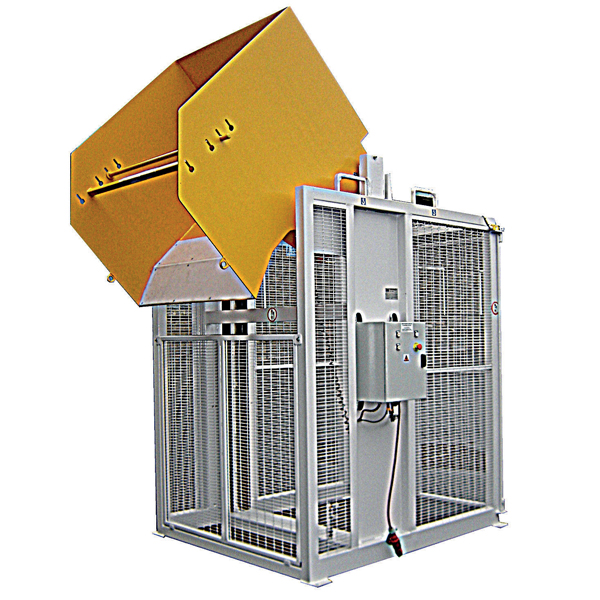

Le choix d’un équipement de manutention que ce soit inclineur, table élévatrice, élévateur, videur, basculeur de caisse est fonction du mouvement à effectuer. Certaines variables sont ajustables afin de rejoindre une position ergonomique, comme la hauteur de déversement, la hauteur de dépose ou l’angle de rotation.

Voici donc un petit guide qui vous aidera à vous y retrouver dans le monde de la manutention…

- Lever, incliner ou retourner ?

Pour adapter votre poste de travail, il faut analyser le mouvement à réaliser, pour cela il peut être intéressant de faire appel à un ergonome.

Nous proposons des appareils de manutention sur-mesure adaptés aux contraintes du client. Le bureau d’étude intégré au sein de la société Manergo imagine et conçoit les appareils des solutions participant à la lutte des TMS.

Lever : L’élévation permet de mettre à hauteur le poste de travail, cela peut être pour des manipulation de déchargement ou chargement ou pour des actions répétitives. L’élévation peut se faire via une table élévatrice, un Lève palette ou un élévateur inclineur. Chacun de ces gammes de produits présentes leurs avantages et répondent à une utilisation précise.

Incliner : L’inclinaison d’une caisse permet d’accéder plus facilement à son contenu, en effet pour rejoindre le fond d’une caisse, l’opérateur(trice) doit se pencher largement. De manière répétitive ce geste peut entrainer un sérieux handicap. Les appareils de manutention effectuant une inclinaison participent à la réduction des TMS, en réduisant le mouvement du dos pour l’opérateur(trice)

Basculer : Vidanger, vider, retourner, basculer sont des mouvements courants en entreprise, et ce quelques soit le secteur d’activité. En effet pour l’approvisionnement de ligne de production par exemple, un contenant doit être basculer. Cette bascule mécaniquement opérée permet d’éviter à un/une opérateur (trice) d’effectuer un prélèvement répétitif

- Comment gérer la sécurité de ma ligne ?

Lors de la rédaction du cahier des charges, le client décide du niveau de sécurité. En effet l’appareil peut être positionné dans une enceinte complétement sécurisée, ou à l’opposer dans un environnement dangereux. Nous nous adaptons aux besoins avec différents niveaux de sécurité.

- Quelle énergie est à mettre à disposition ?

Selon votre infrastructure nous adaptons les systèmes régis par une énergie électrique ou pneumatique. Nous prenons compte de vos contraintes pour respecter vos puissances dispoinible.

- Comment définir mon besoin ?

Pour vous accompagner dans votre démarche d’amélioration continue, vous pouvez faire appel à un ergonome. De plus vous pouvez contacter notre équipe commerciale qui forte d’une grande expérience pourra vous aider et vous aiguiller vers la bonne solution.

Contactez nous

Contactez nous